About us

Accessible Automation, Born from the Lab, to Free Researchers

At Cellaven, everything started with a simple observation: too much time, too much energy, and too much expertise are consumed by repetitive, time-consuming manual tasks, often performed in uncomfortable conditions.

Julien, a passionate biologist, experienced this reality firsthand for years. Between pipetting, media changes, and long hours under the hood, he saw research slowly dissolve into routine. What he witnessed was a waste of scientific time, and the frustration of not being able to focus more on what truly matters, Science.

The Challenges of Manual Cell Culture

Julien identified three systemic barriers that limit the efficiency and rigor of cell research:

- A loss of scientific added value: every hour spent on manual handling is an hour lost for analysis, critical thinking, or experimental design

- A lack of reproducibility: manual gestures vary from one operator to another, these often-invisible differences undermine result reliability and experimental reproducibility, both fundamental pillars of science

- An increased risk of contamination: the more human intervention, the greater the chance of compromising an experiment, a single contamination can wipe out days, weeks, or even months of work

The obvious answer to these challenges was to automate the manual aspects of cell culture.

But Julien quickly realized that existing solutions weren’t suited to the needs of R&D labs: they were prohibitively expensive and overly complex.

This realization marked the beginning of Cellaven.

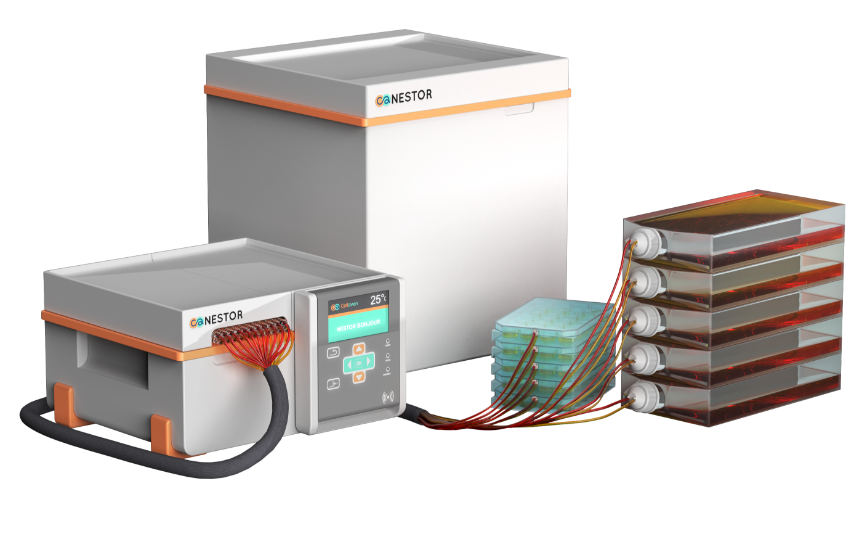

Our Innovation: an Affordable, Compact, and User-Friendly Automation Specifically Designed for R&D

Aware of this need, Julien had a clear vision, to design a machine capable of automating cell culture, accessible to all labs, and capable of overcoming the limitations of existing solutions.

- Affordable: because automation should be within reach of labs of all sizes, not a luxury for the few

- Compact: with a footprint as small as an A3 sheet, because space is always at a premium in the lab

- Compatible: no proprietary consumables, no need to rewrite protocols, the system works with standard flasks and plates, to accommodate scientists’ existing workflows

- Easy to use: no need to be an engineer or a programmer, Nestor is designed for biologists, enabling a quick start and smooth operation every day

From a Garage Prototype to a Growing Global Presence

The first Nestor prototype was built in Julien’s garage, using the family’s 3D printer.

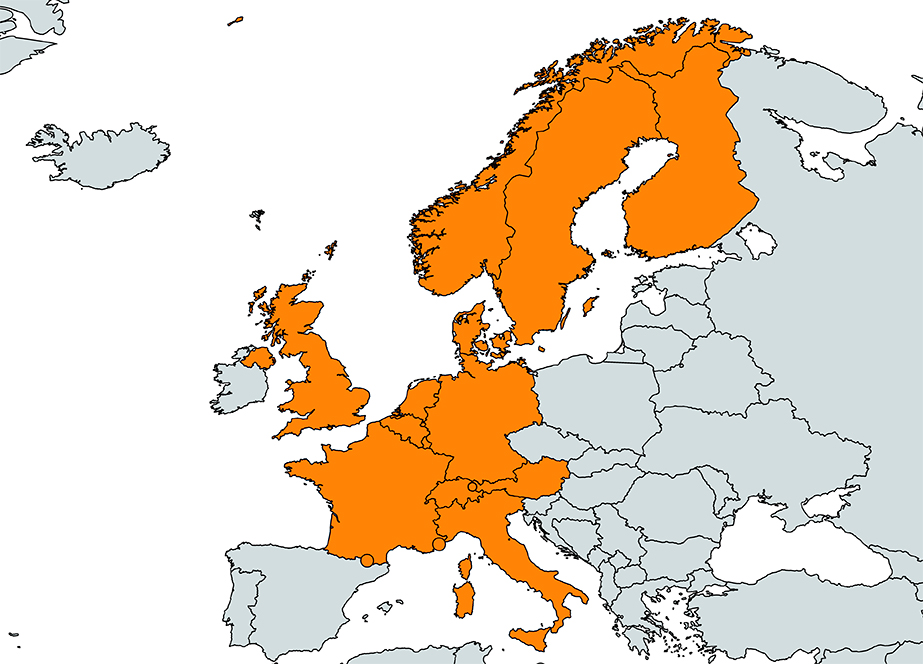

Today, Nestor is used in over 13 countries across Europe, distributed by leading networks, and supported by a dedicated team who bring Cellaven’s mission to life.

And the international expansion continues.

Our mission is simple and ambitious,

We are scientists serving scientists. And we’re proud of it.